Metrological requirements verification

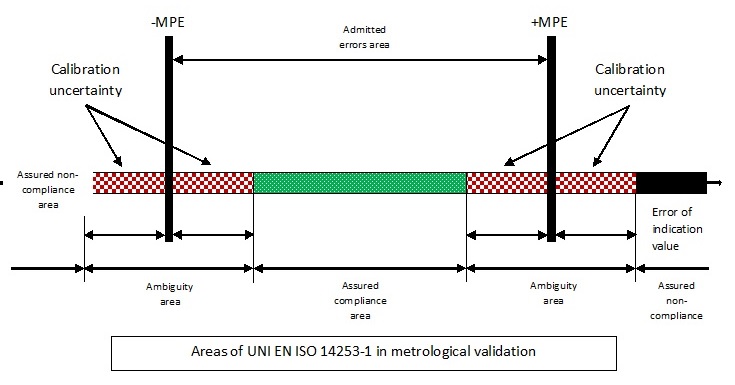

Measuring instruments are used to verify that products features fall within the tolerances prescribed by the technical specifications of the products themselves. According to UNI EN ISO 14253-1, the product is compliant if the measured value falls within an area obtained by reducing the area of measurement uncertainty. The metrological validation, which is made after the calibration, compares the calibration results, which are the instrument errors, with the user-defined maximum permissible errors (MPEs) and a safe compliance zone can be determined.